Waterproof, Water-Resistant, & Moisture Resistant

The performance of floor coverings depends on many variables and not just one. I

teach this to anybody and everybody willing to learn more about the science of floors. This is

always an ongoing topic of conversation in the Hodges Wood Products Lab at NC State

University. We are constantly evaluating multiple properties of both domestic and

international products to help the industry understand the differences between product

categories and performance levels. A few years ago, the topic of “water-resistant” came into

the mix as one of the properties to be evaluated. Since then, we have worked on different

methods to assess this property and to properly understand what this means for in-service

applications.

Whole plank test

Walking around DOMOTEX USA, we will find whole products submerged in fish tanks. The

display presents how a product in its manufacturing configuration can be subjected to any

amounts of water without changing its dimensions or properties. This display is commonly

used for products where no components absorb water. In a laboratory setting, this test could

measure dimensional changes like thickness and squareness as well as change in weight.

The downside of this test is that no single plank is installed on its own and, in many cases,

planks are cut for layout dimensions. This test can also be time dependent. While some

products can withstand these conditions for a short period, others can handle much longer.

As an alternative to a submerge test, products can also be placed in a high humidity

conditioning chamber.

Whole piece in high humidity chamber

Whole piece in high humidity chamber

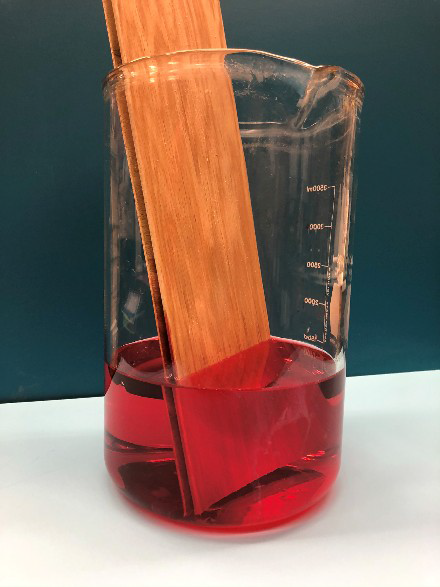

Less-than-whole plank test

This type of test evaluates the performance of a section of the flooring product. For this

reason, the manufactured product receives at least one cut in order to expose the core of

the product and show the effect of water or moisture on the properties of the material. This

test can evaluate the same properties as a whole plank test except the manufacturing

tolerances on the cut edge. The cut on the product also removes any protection that may be

present on the joints of the product. Variants of the test include different numbers of cuts.

The simplest version involves one cut edge while more complicated tests include the cutting

and exposing of all sides and even parts of the top or bottom of the planks. When subjecting

the product to water the floor can be fully submerged or partially submerged. Partially

submerged methods allow us to determine capillary moisture movement, rate of absorption

inwards and differences between the edges and middle of a product.

Partially submerged test

Partially submerged test

Assembled product test

An assembled product test derives from the understanding that a single piece of flooring is

not put in service by itself. These types of tests try to replicate in-service conditions to

understand the performance level of a product. Settings can be as large as 9’ x 6’, like

international methods under different environmental conditions, to multiple T-joints, like the

North American Laminate Floor Association’s (NALFA) topical moisture resistance test. This

last test looks at the ability of an assembled product to withstand the effects of surface

water while holding the water on the surface. While this methodology was developed for

floating floors, modifications can be made for other installation methods. Understanding how

a flooring system performs versus a single flooring element is of great importance. Products

need to perform under service conditions and not in isolation.

Topical moisture test

Topical moisture test

Floor coverings within the building envelope

An important final consideration is to remember that our products live within a larger

structure. In both residential and commercial settings, flooring systems have to properly

handle moisture and water interactions. Our products are not only exposed to the

living/work/recreational environment but are also in contact with subfloor structure,

membranes, padding, barriers, heating systems and a variety of elements on top, beneath

and around the flooring covering. Different flooring products use different methods to limit

the effect of water, but all of these methods have to be in harmony with the building

envelope. The whole system must withstand the effect of water or we may be exposing

ourselves to unforeseen water problems instead of preventing them.

About the Author

Guillermo Velarde is the Manager of the Hodges Wood Products Lab

Guillermo Velarde is the Manager of the Hodges Wood Products Lab

within the Department of Forest Biomaterials at NC State University. He

is a leader in University-Industry collaborations serving the domestic and

international flooring industry. The Hodges Lab holds memberships to

NALFA, NWFA, DHA, as well as other suppliers and user associations.

Guillermo currently engages with installers and inspectors through

trainings and seminars hosted by multiple wood industry associations.

Guillermo was recently recognized by Hardwood Floors Magazine as one

of the forty under 40 in the Industry (2019). He has partnered with

DOMOTEX USA since the inception of the event.